Challenging the Pitot tube: Optical air data

- Andreas

- Sep 19, 2022

- 5 min read

Updated: Sep 20, 2022

The measurement of air data has always been one of the most important sensing problems for aerospace engineers. While there are several derivatives of the classical sensors, such as the Kiel Pitot tube or multi-function probes, they all follow a similar concept. In this article, we look at an alternative method that uses fundamentally different ideas to obtain air data. Sounds too futuristic? As we shall see, the future is already here…

The classics: Good, but far from perfect

The “classical” air data sensing elements, such as Pitot tube, static ports and angle-of-attack (AoA) vanes are well-established but certainly have their drawbacks, as some of them protrude into the air flow and are prone to ice accretion and bird strikes. From a military perspective, they tend to get in trouble at very high AoA or angle-of-sideslip (AoS) and can be detrimental to aircraft stealth [2]. Also, they cannot measure air data at a distance. This would be useful for some applications. What, if there would be a technology that remedies all that? Enter: Optical air data.

Laser-Doppler anemometry

The flow velocity measurement by optics has been used in laboratories for a significant amount of time. In particular, the use of laser anemometers has proven to be successful [2]. Figure 1 depicts a 2D-laser-Doppler anemometer permitting flow-velocity measurement in two axes. While there are other optical flow velocity measurement methods, we will focus on the laser-Doppler anemometer to understand the principle.

Here is how it works in simple terms [2]: A laser beam is generated and then spit into two sub-beams that are coherent and focused at the measurement location. This creates a “fringe pattern” (a pattern of parallel lines) that are orthogonal to the velocity measurement axis. A particle crossing the measurement volume then generates a scattered beam that is analyzed in a detector. The frequency of this “burst” is directly related to the velocity component that is normal to the fringe lines. For multi-dimensional measurements, a second set of beams can be added (see Figure 1).

Obviously there are many technical details attached to this and the interested reader is redirected to [2] for a more thorough description.

Far beyond velocity

The measuring capabilities of optical air data go far beyond velocity. Most manufacturers of optical air data systems also provide options for density, pressure, temperature or even humidity [3].

A quick excursion to physics: The air density can be determined by measuring the magnitude of backscattered light. There are two main components of backscattered light (see Figure 3): the aerosol backscatter (large amplitude) and the molecule backscatter (lower amplitude) [2]. The two fundamental mechanisms are Mie scattering for aerosols and Rayleigh scattering for molecules. It is the molecular scattering that is of interest for the density and temperature measurements.

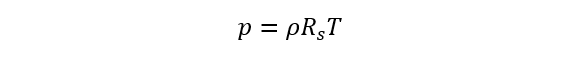

Temperature is measured by analyzing the spectral width of the Rayleigh-scattered light [2]. Ultimately, the static pressure can be calculated using the ideal gas law:

At this time, most systems are quite bulky and used in a laboratory environment, there are however good examples of in-flight applications (see below).

Application: Air data system calibration

So, how about using this technology to calibrate air data systems of new aircraft? It turns out, that works quite well, especially because the optical system is able to measure the parameters outside of the area that is disturbed by the airframe [4].

Several manufacturers have successfully used optical air data systems for calibration of “conventional” air data probes [2]. Figure 4 shows such an installation on a transport category aircraft during the flight test campaign.

A flying testbed

The national aerospace laboratory of the Netherlands (NLR) performed a flight test campaign under the NESLIE (New Standby Lidar Instrument) project using their Cessna Citation research aircraft in 2009 [4]. The laser heads were installed in the escape hatch of the door (see Figure 5).

This experiment permitted a direct comparison of the optical data with measurements obtained from the conventional sensors. The correlation analysis can be seen in Figure 6 and Figure 7:

TAS measurements by the optical system (TAS neslie) correlated strongly with the conventional data (TAS air data) over a wide speed range. The correlation of AoA data showed a constant offset, which was attributed to the flow field near the measurement location.

The optical data (AOA neslie) was measured near the escape hatch and therefore shows some offset to the boom AoA values (AAB calibrated). The correlation was also depending on the sideslip angle, as was expected. A careful selection of the optical measurement location is therefore absolutely essential. Currently, the German Aerospace Center (DLR) is conducting a series of tests on a Falcon 20 aircraft, further advancing optical air data and demonstrating its usefulness [5].

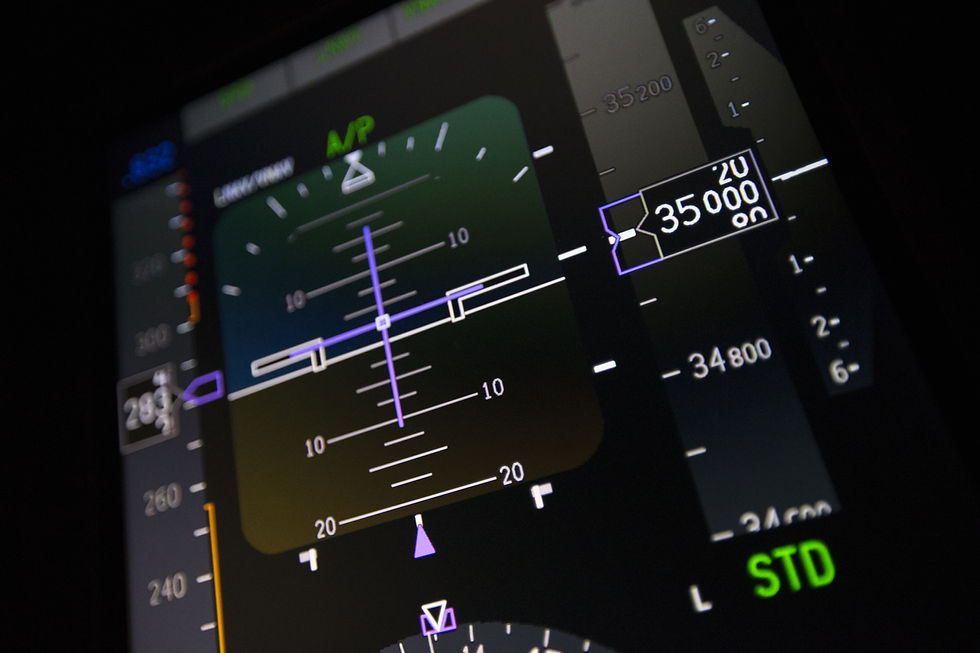

A word about airspeed

As pilots and aerospace engineers, we know that the “airspeed indicator” onboard an aircraft really is a bit of a misnomer. In fact, the airspeed indicator (without any instrument and position error) does not show a speed in the physical sense, but rather a quantity that is related to “impact pressure” (the difference between total pressure and static pressure) [6]. With knowledge of the temperature, the density can be calculated and True Airspeed (TAS) obtained. The optical instruments will of course measure TAS directly.

For those with a passion for physics and for those who feel like refreshing the airspeed calculation principles, the magic formulas are added below [6]:

Airspeed calculation - back to basics

It will be clear to most readers, that instrument and position error can produce a difference between Indicated Airspeed (IAS) and Calibrated Airspeed (CAS). On modern high-performance aircraft, this is usually accounted for by an error model in the air data computer [6].

Assuming zero instrument and position error, the airspeed indicator will show Calibrated Airspeed (CAS):

Notice, that only total pressure (pt) and static pressure (ps) need to be measured for this calculation, as the rest are constants! (This equation could historically be built in a mechanical instrument, as opposed to the TAS equation).

If we now replace the static pressure at MSL (p0) by the static pressure at the aircraft (ps), we obtain Equivalent Airspeed (EAS):

Often, this step is referred to as “compressibility correction”, which is another slight misnomer, as the formulas are all based on compressible flow. It is more of a pressure altitude correction, as the engineers of Boeing [6] and AIAA [7] phrase it.

In the US literature, this correction is often referred to as the “f”-factor, which is defined as follows:

Inspecting the above equation, we see that the f-factor only varies with total pressure (pt) and static pressure (ps), as the other parameters are constants [7]. This is the foundation for the famous EAS/CAS conversion charts.

The last step involves replacing the density at MSL (ρ0) with the density at the aircraft (ρ) in order to obtain True Airspeed (TAS):

It is therefore clear that that TAS is equal to CAS only at MSL, on a standard day. The density is usually obtained by measuring the temperature and applying the ideal gas law (see above).

The term “dynamic pressure” is defined as shown below:

Therefore, a constant EAS yields a constant dynamic pressure for all altitudes. This is important for structural loads, as the aerodynamic forces depend strongly on dynamic pressure.

Notice the nuance between dynamic pressure (above) and impact pressure:

Impact pressure is the difference between total pressure and static pressure:

Dynamic pressure is very close to impact pressure for aircraft that fly less than 250 KCAS and below 10’000 ft. This is probably why that nuance is so often overlooked.

References:

[1] Wikipedia, «Wikipedia,» NASA, [Online]. Available: https://de.wikipedia.org/wiki/Laser-Doppler-Anemometrie#/media/Datei:Laser-Doppler.jpg. [Zugriff am 17 09 2022].

[2] NASA, «NASA/TP-2004-210735: Optical Air Flow Measurements in Flight,» NASA, 2004.

[3] M. Fraczek, A. Behrendt und N. Schmidt, «Short-range optical air data measurements for aircraft control using rotational,» Optical Express, Bd. 21, Nr. 14, p. 148–166, 2012.

[4] NLR, «NLR-TP-2010-436: In-Flight Evaluation of an Optical Standby Air Data System,» NLR, 2010.

[5] DLR, «Optical Air Data,» DLR, 09 2022. [Online]. Available: https://www.dlr.de/content/de/artikel/news/2022/03/20220824_vom-labor-in-die-luft-flugdaten-messen-mit-laser.html. [Zugriff am 09 2022].

[6] BOEING, Jet transport performance methods, 2009.

[7] T. Yechout, Introduction to aircraft flight mechanics, AIAA, 2003.